Company Profile

Shanghai Dongda Chemical Co., Ltd. now has 100,000 tons of polyether polyol-50,000 tons of polyurethane waterproof material and modified silane sealant co-production device. It adopts domestic advanced DCS fully automatic control system, and strives to become the most influential in China. ODM and OEM OEM production bases for waterproof and sealing materials.

In the industrial assembly and production, due to the structural bonding between the components, the existing joints are easy to become a passage for air and water leakage. Therefore, it is necessary to use a sealant with environmental protection, mildew resistance, yellowing resistance and the like. Knot sealing treatment.

Shanghai Dongda MS930 industrial modified silane sealant not only meets the sealing requirements of automobiles and containers, but also meets the requirements of bond strength in rail transit and elevator industry. It has other types of sealant in environmental protection, mildew proof and yellowing resistance. Unmatched advantages.

Industrial bonding for a variety of substrates

MS930 modified silane sealant can be effectively bonded to a variety of materials to achieve a good bond sealing effect.

Modified silane sealant in the RV

Modified silane sealant at the rib on the back of the elevator

Low VOC safety, environmental protection and pollution

Shanghai Dongda MS930 silane modified sealant contains no solvent, no irritating odor, low VOC content, no toxic and harmful substances after curing, safe and environmentally friendly, no pollution, and a green development path.

Organic sealants with anti-mold effects generally contain free formaldehyde and have a certain taste, which is very harmful to the human body. Shanghai Dongda MS930 modified silane sealant does not contain formaldehyde

Modified silane sealant for containers

Excellent mildew resistance, yellowing resistance

Assembled and spliced joints are the key parts for sealing and sizing to prevent water and air. Especially in East China and South China, the weather is damp and it is more likely to breed mold, which not only affects the appearance but also brings certain harm to the human body. Due to its special formulation system, Shanghai Dongda MS930 modified silane sealant has better anti-mildew effect than other types of anti-mold glue, and has strong anti-mildew ability, and has an extraordinary advantage in anti-mildew ability.

Modified silane sealant at the seam of refrigerated truck

Product introduction

MS930 industrial modified silane sealant is a one-component non-sagging sealing material, which is made of the most advanced modified silane polymer.

During the construction, the glue is used to sizing the joint to form a waterproof sealing system with high efficiency, mildew proof, environmentally friendly, odorless, long-lasting yellowing resistance and good adhesion to various substrates.

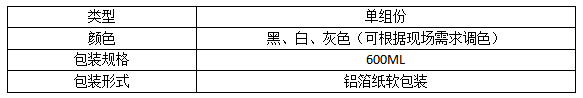

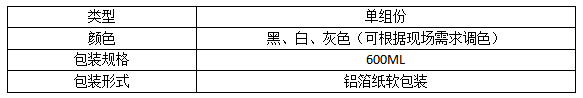

Traits and packaging

Traits and packaging

Scope of application

Automobiles, RVs, containers, elevators, etc. have industrial fields with bonding strength, environmental protection, mildew resistance and yellowing resistance.

Performance characteristics

The highest anti-mildew grade, anti-mildew effect lasting;

Formaldehyde-free, solvent-free, environmentally friendly, no odor;

Good adhesion to a variety of substrates;

Contains no silicone oil, no risk of oil diffusion, no corrosion to the substrate, no pollution;

Single component, good extrusion performance and easy construction.

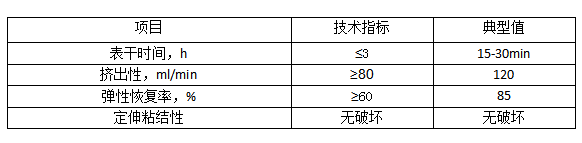

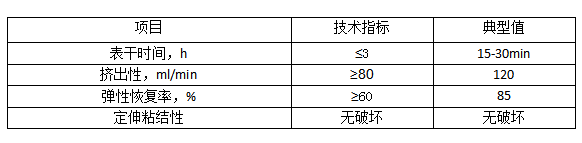

Technical indicators

Implement the standard requirements of JT/T881-2011 "Container Sealant".

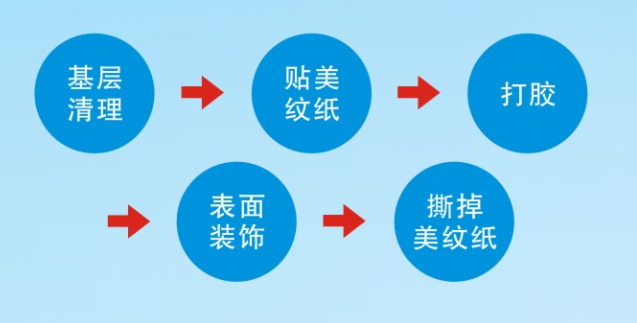

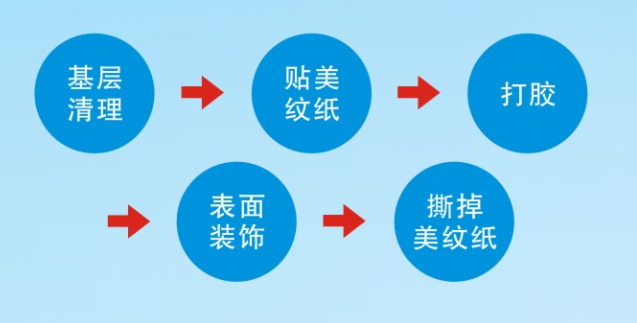

Construction process

Construction Notes

1. Before use, ensure that the sealant is in the warranty period. Please use it within half an hour after the nozzle is cut open;

2. If the rubber outlet of the nozzle is hardened, the remaining sealant can be used after cleaning the cured glue.

3. The sealant before curing should avoid contact with eyes and skin. If contact with skin, first scrub with soapy water or alcohol, then rinse with water; if contact with eyes, first

4. Rinse with plenty of water and seek medical attention if necessary.

5. An environment with insufficient ventilation or low humidity will slow down the curing speed.

6. Do not discard uncured sealant into sewers, water or soil.

7. The glue joint should be full and free of air bubbles, and it should not be replenished. The depth and shape meet the design requirements.

Storage and transportation considerations

1. During transportation, it should be protected from moisture, rain, sun, high temperature, and away from heat.

2. The product should be stored in a ventilated, dry, cool place to prevent direct sunlight.

3, isolate the fire source, away from the heat source, the storage temperature should be 5-30 ° C

4. The shelf life is 9 months under sealed conditions.